This one came to me for a very intermittent no start. The customer has been driving it like this since he purchased it a few months ago. It was becoming more frequent lately.

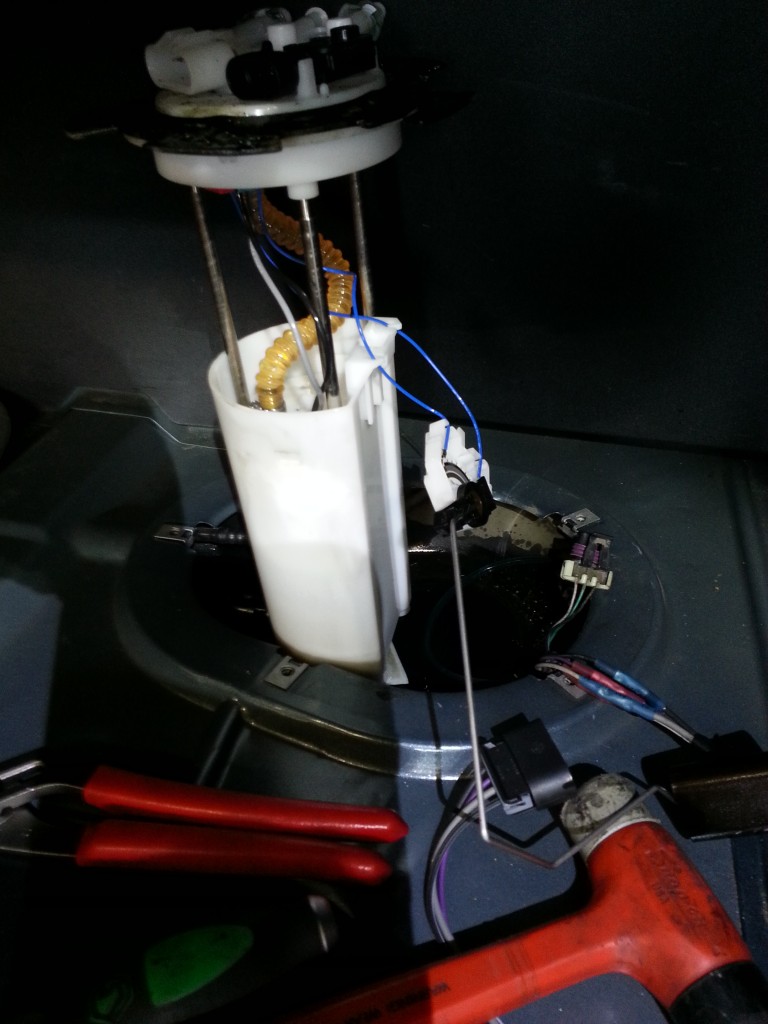

I was called to check it out at his work. The car would crank over but wouldn’t start. The S model is super charged and it requires an hour’s labor just to check fuel pressure and it also requires a special adapter that is Mini specific. I didn’t want to waste an hour of this customer’s money to check fuel pressure. I gave the intake a shot of fuel and the car started and died. I told the customer it will require a fuel pump and a fuel pump relay.

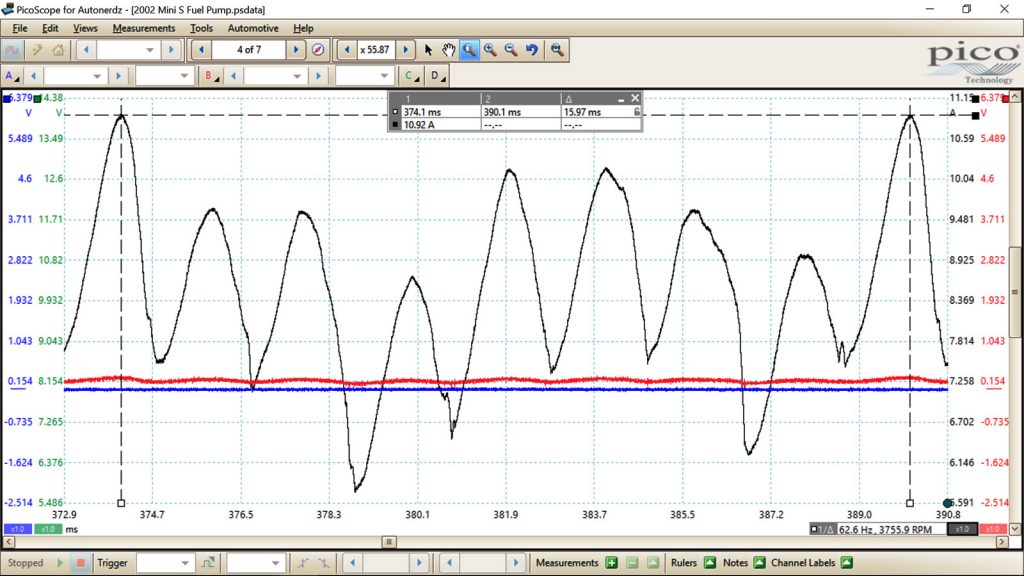

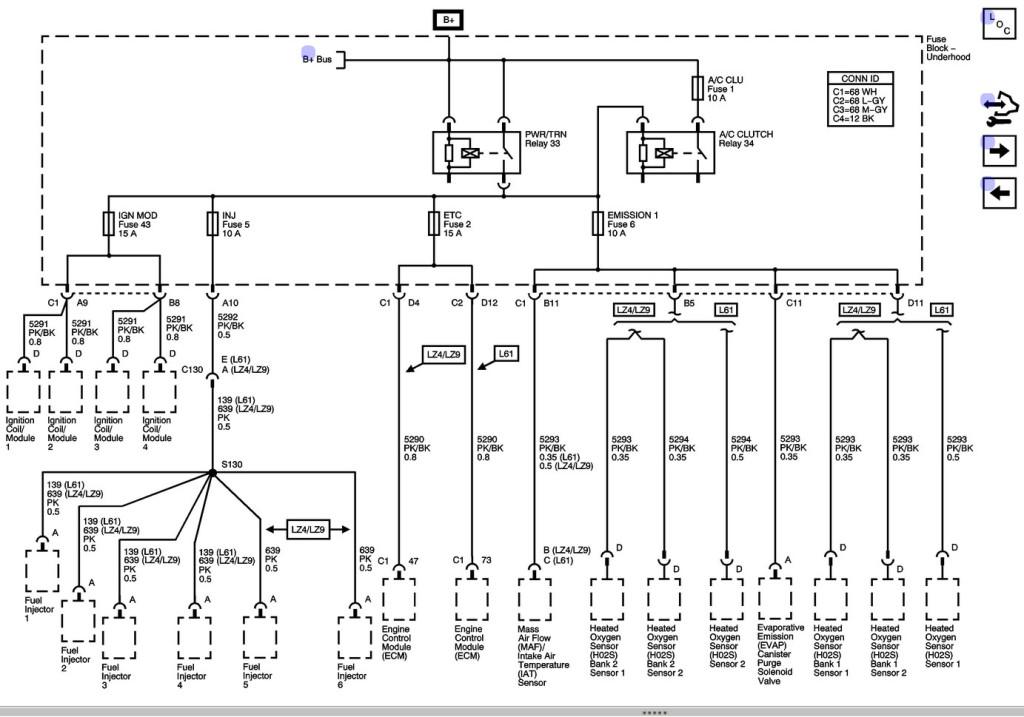

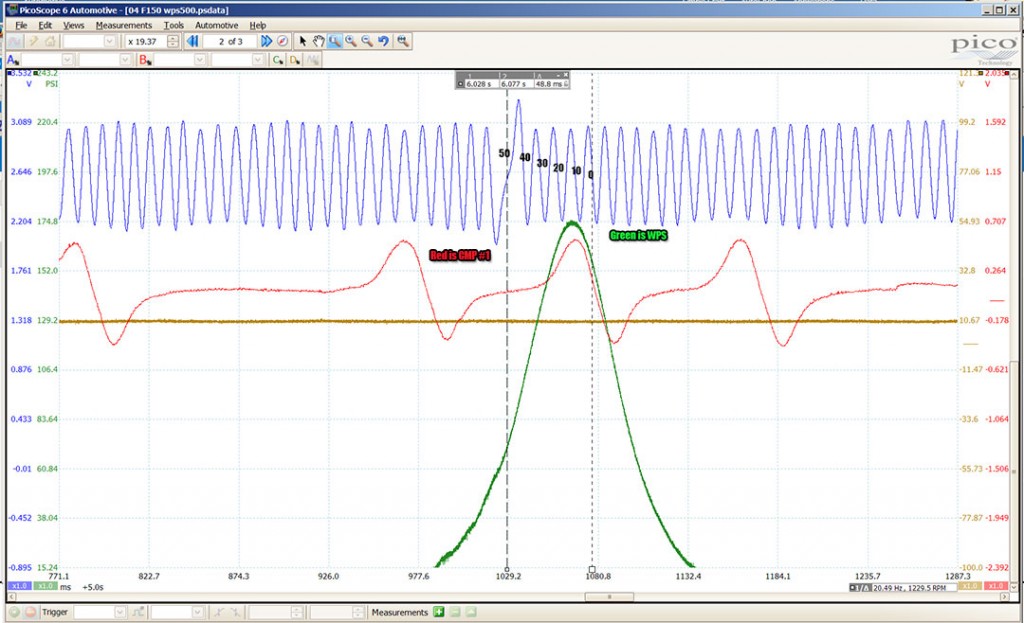

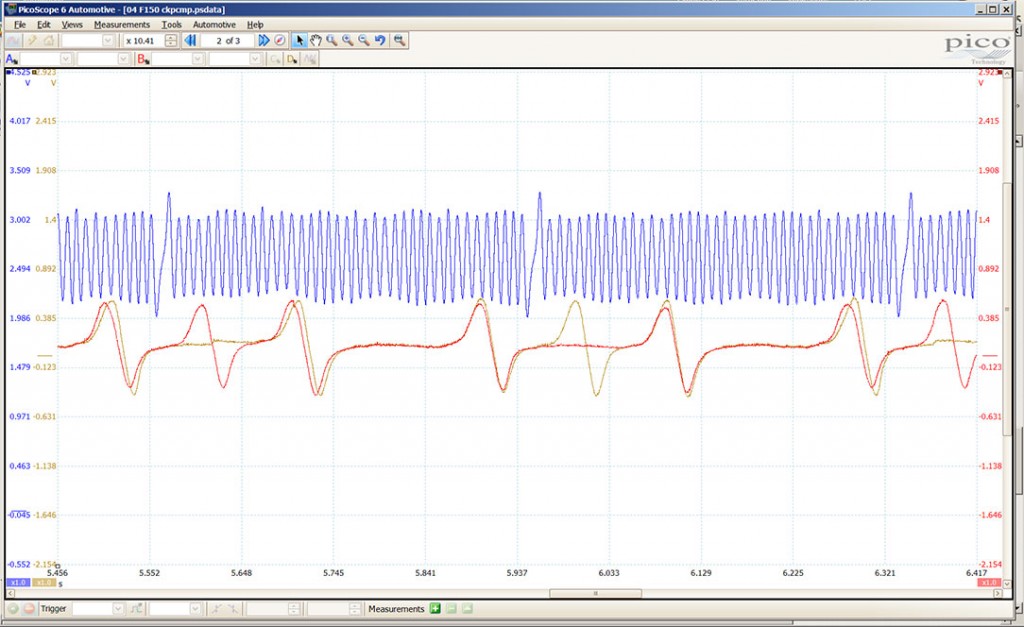

After leaving, the customer called me back and said his car now starts and runs again. Before I left, we discussed the issue with the pump and the most likely cause of this condition. The customer was unsure of my finding, but he decided to trust me and ordered the fuel pump and relay. The parts came in and I decided to current ramp the old fuel pump before removing it. This would allow me to show the owner what I was talking about and why I didn’t want to remove his super charger’s inter-cooler to verify that the fuel pump pressure would have issues, too. Here’s the waveform using my Pico Scope. As we see in this image, the amperage draw from the pump is 5 amps higher than normal. We also see that the commutator segments are showing poor contact at the brushes. We see the pumps RPM’s are low by almost 3000 RPM’s.

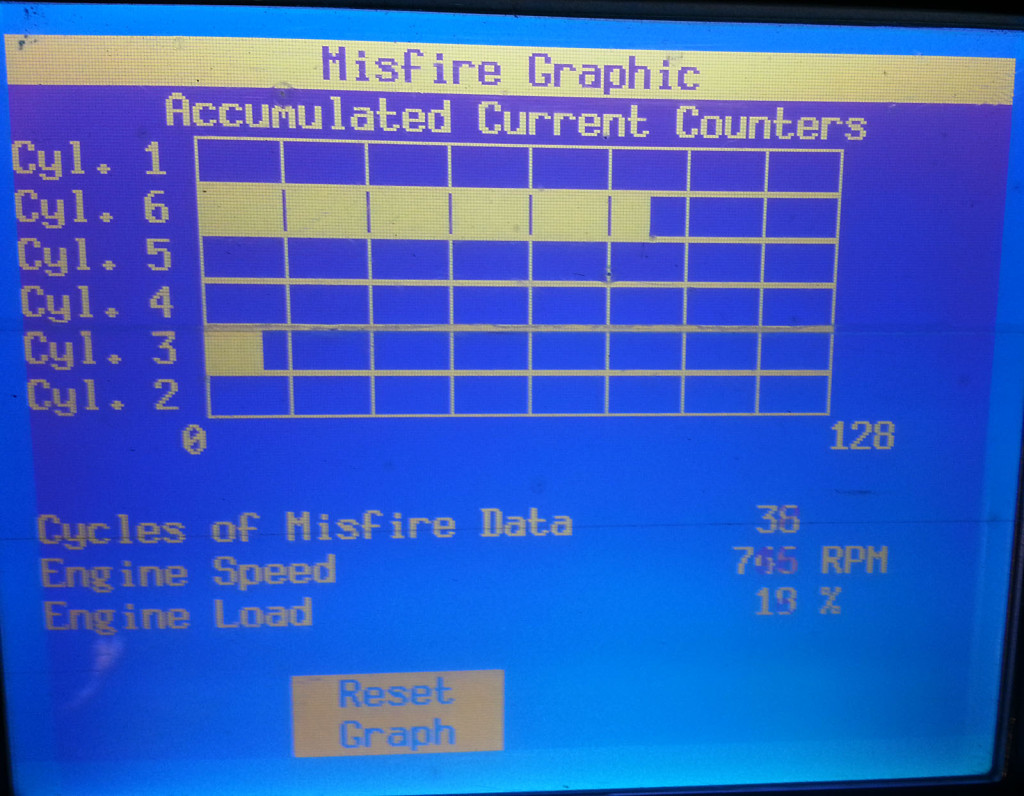

It’s clear the pump is bad. The high amperage and low RPM’s are part of the cause of this intermittent no start complaint. The pump’s brushes have poor contact with the commutator segments and are losing the ability to rotate the armature at startup. This causes the intermittent no start problem and explains why it can sometimes still start and run. The low RPM’s will cause low fuel pressure. This can and will cause other driveability problems. This one had 2 stored DTC’s, a P0300 and a P0302. Replacing the pump also corrected these 2 DTC’s without needless replacement of other parts.

This customer is very happy and even called me later to thank me for fixing his car without needing to replace unnecessary parts. He was also happy because we didn’t need to waste money with prolonged diagnostic work by removing the super charger’s inter-cooler to verify that fuel pressure was also an issue.

Sometimes there are better ways to do things and this was just such a case. I always recommend that you know who is working on your car and if they’re qualified to do the work, do it properly without wasting your hard earned money.