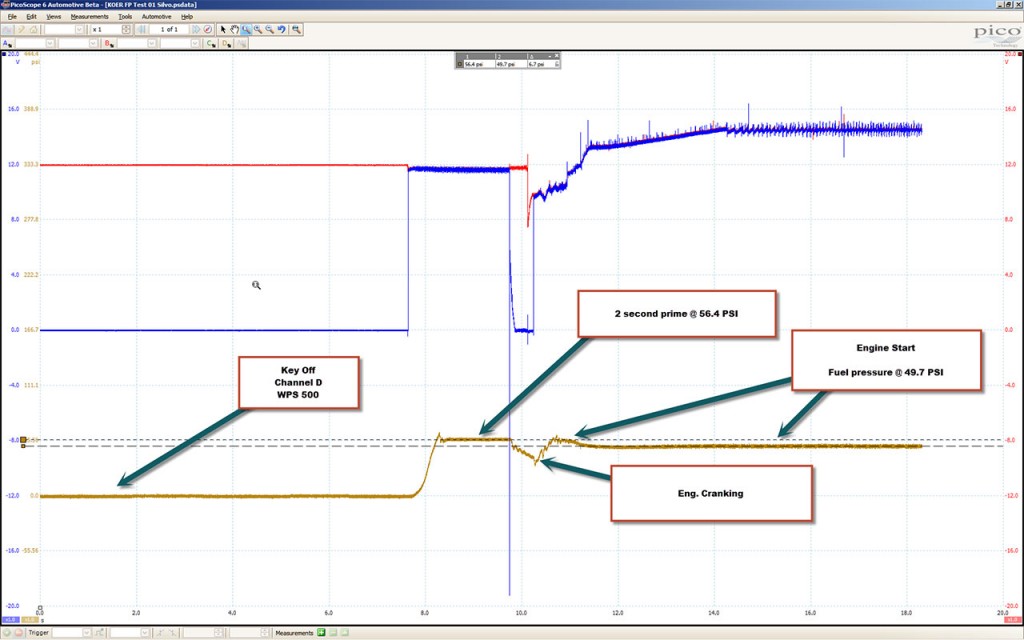

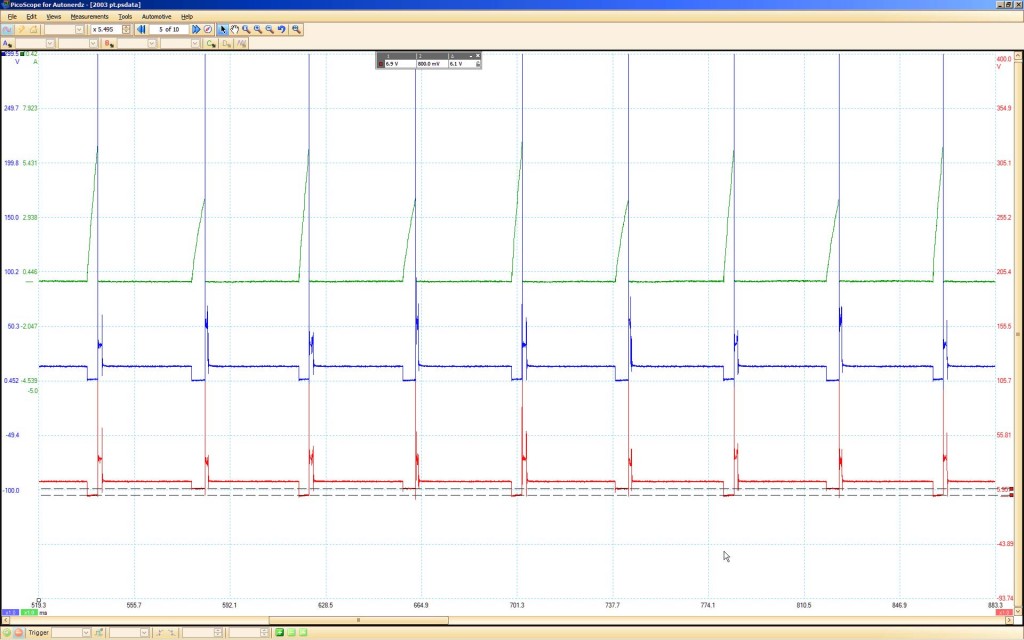

This one came to me from another shop. They wanted me to replace and program the PCM for a misfire problem. They’ve had this one to the dealer and still didn’t get the problem fixed. They replaced the ignition coil twice. They replaced all the spark plugs and wires. All 4 injectors and the MAP sensor. The customer has been driving it like this for 8 months. After performing the basic diagnostic inspection, I informed them a PCM replacement wouldn’t fix the problem. They let me run some advanced diagnostics with my Pico Scope. It only took about an hour to find the problem. Even the dealer couldn’t find and fix this one. Here’s a capture of the problem found with the Pico.

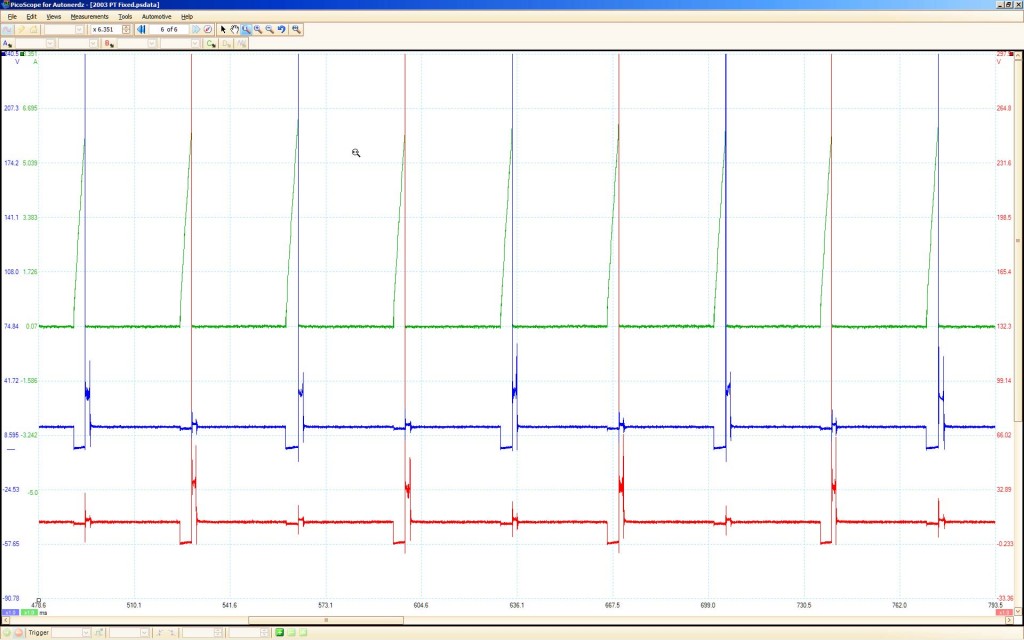

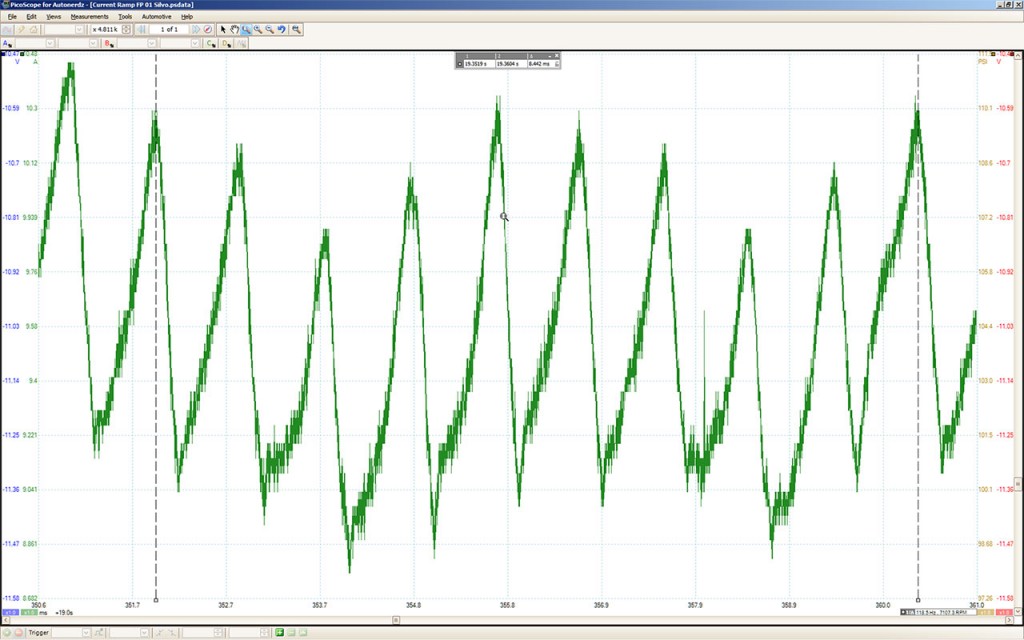

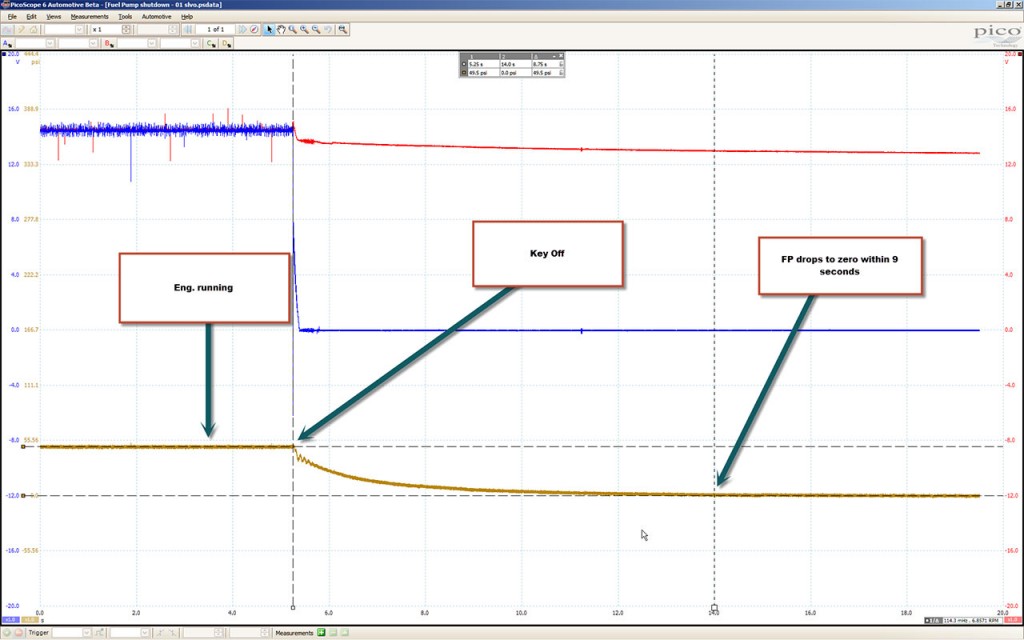

The top image shows ignition coil amperage issue’s on the #2-3 coil. Look at the peak amperage for the 1-4 and 2-3 coils and you’ll see the fault. I found the wires crossed in a connector that was replaced. I don’t know who did the work, but after correcting the wiring problem the vehicle ran great and the MIL lamp never came back on. A PCM for this car costs $700.00 dollars plus programming. It’s not a returnable part. It would have been almost $1000.00 dollars wasted. Here’s a capture after the repair. This customer was extremely happy to have her car back and running better than ever. Bottom image shows the proper coil amperage after the repair was made. A simple wire repair was the only problem and this customer has spent over $2600.00 dollars trying to fix it with no results.