This customer had been to the dealer for some random electrical problems. He decided not to have the dealer work on his car after a long conversation with the service writer. He called me to come out and look at his vehicle. I did some basic diagnostics and found a few DTC’s in 6 modules. Most were communication problems on the Class 2 data buss. I did some voltage drop tests and found the electrical system had a 900 MV voltage drop on the ground side. After some circuit integrity work the voltage drop was brought down to 52MV. 100 MV is the expected limit on the main 12 volt power system. This resolved the abnormal electrical issues and the customer was very happy with the results. The dealer wanted to charge over $200 dollars to just look at it and claimed it might need a PCM. More guesswork without knowing what is really happening. I also found the vehicle had an HVAC system code and the customer wasn’t sure if he wanted to fix it. After fixing his random electrical issues, he decided to have me fix the HVAC system fault also. The system had a DTC B0429. The IPM stored this DTC from the HVAC module and the controller couldn’t store a proper actuator module calibration. After some diagnostics, I found the actuator was not able to control the 3rd door for the rear A/C controller. This system has auto climate control with 3 zones. Drivers, passengers and rear seat. It was necessary to replace the temperature door actuator module and calibrate it to the system. After all this electrical diagnosis and repair, the customer requested me to do a complete tune-up. Happy customers are always the best customers. Don’t let guesswork diagnosis cost you unnecessarily.

Author Archives: drdiesel1

2003 Chrysler PT Cruiser 2.4L I4

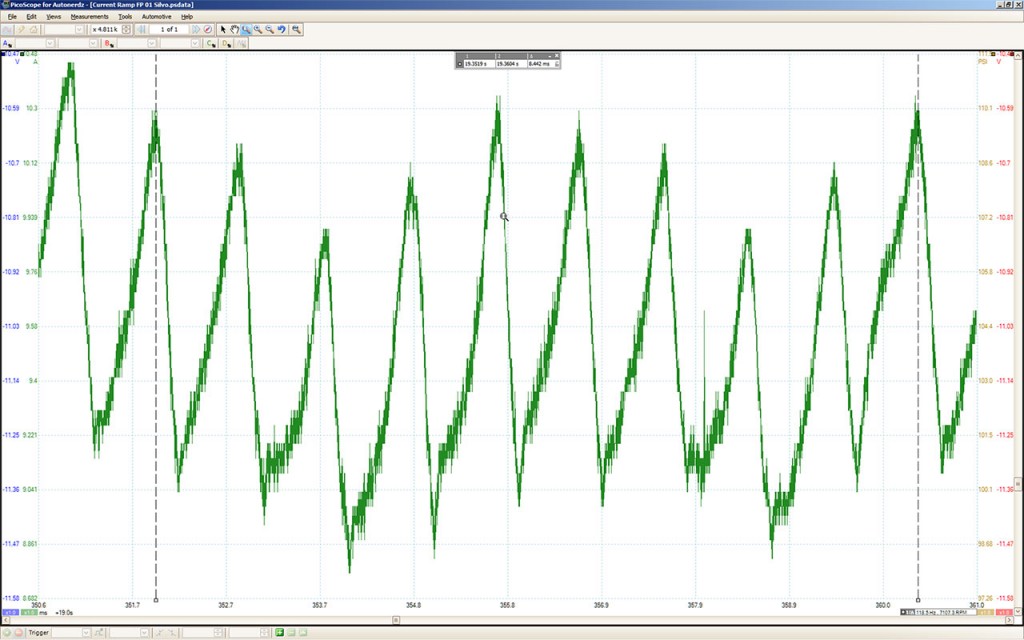

This one came to me from another shop. They wanted me to replace and program the PCM for a misfire problem. They’ve had this one to the dealer and still didn’t get the problem fixed. They replaced the ignition coil twice. They replaced all the spark plugs and wires. All 4 injectors and the MAP sensor. The customer has been driving it like this for 8 months. After performing the basic diagnostic inspection, I informed them a PCM replacement wouldn’t fix the problem. They let me run some advanced diagnostics with my Pico Scope. It only took about an hour to find the problem. Even the dealer couldn’t find and fix this one. Here’s a capture of the problem found with the Pico.

The top image shows ignition coil amperage issue’s on the #2-3 coil. Look at the peak amperage for the 1-4 and 2-3 coils and you’ll see the fault. I found the wires crossed in a connector that was replaced. I don’t know who did the work, but after correcting the wiring problem the vehicle ran great and the MIL lamp never came back on. A PCM for this car costs $700.00 dollars plus programming. It’s not a returnable part. It would have been almost $1000.00 dollars wasted. Here’s a capture after the repair. This customer was extremely happy to have her car back and running better than ever. Bottom image shows the proper coil amperage after the repair was made. A simple wire repair was the only problem and this customer has spent over $2600.00 dollars trying to fix it with no results.

2001 Chevy 1500 Silverado Pickup 4.8L V8

Today’s fun project is a 2001 Chevy Silverado 1500 pickup with a 4.8L V-8

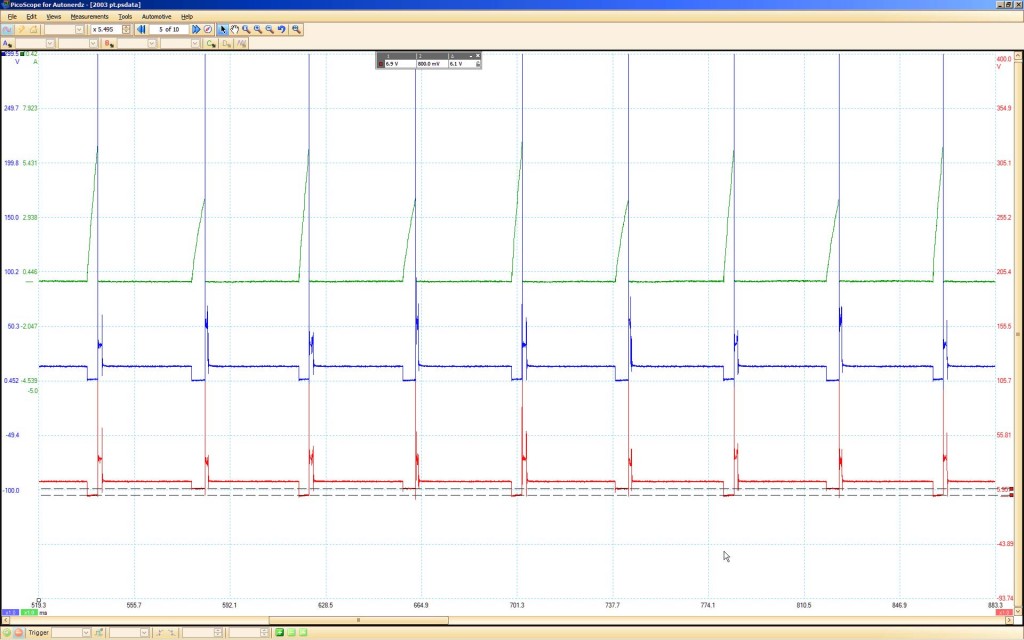

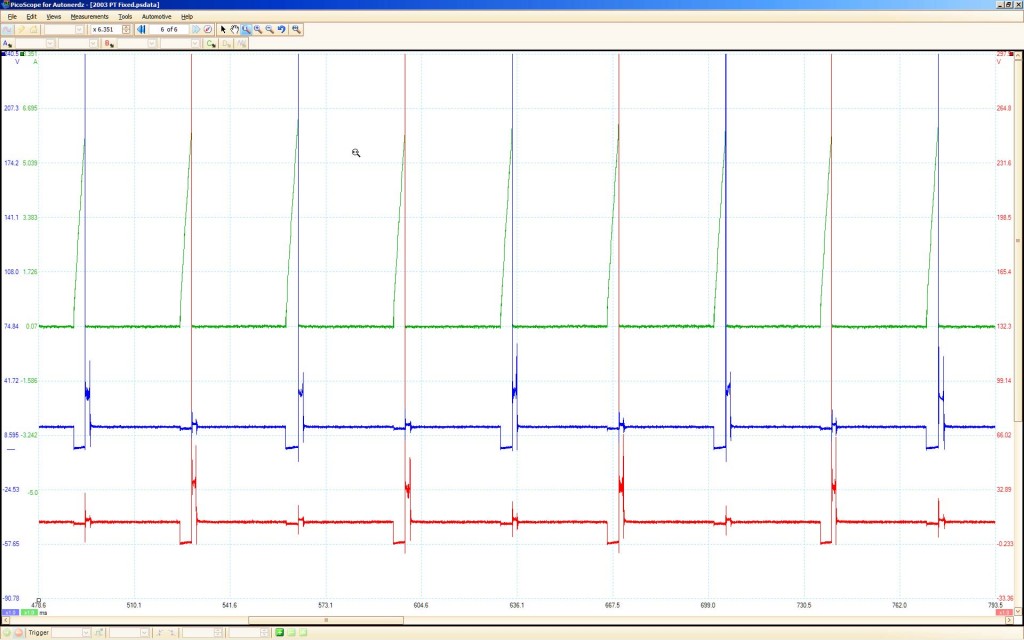

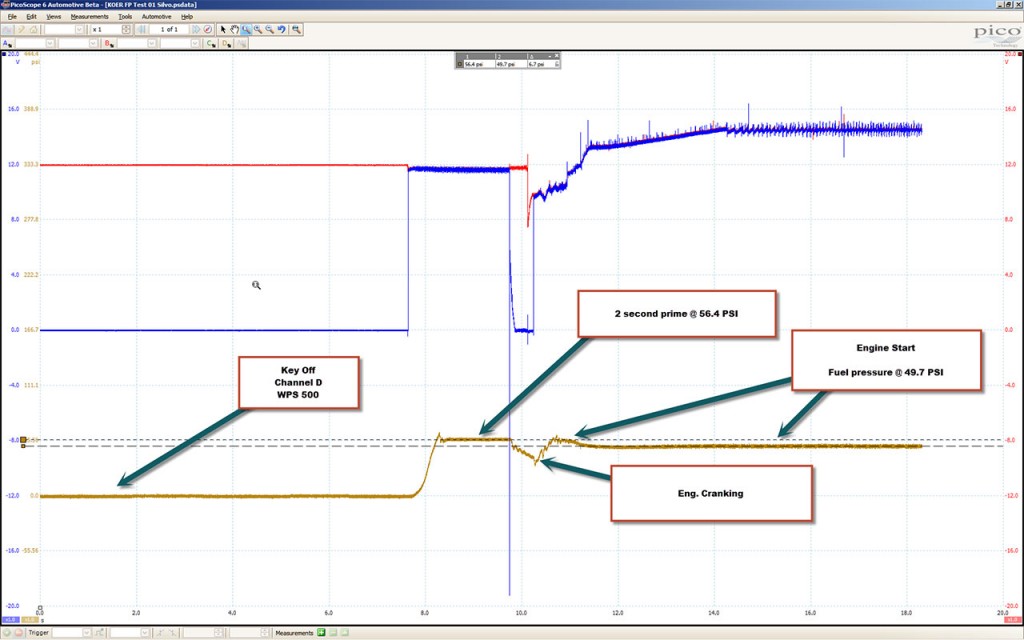

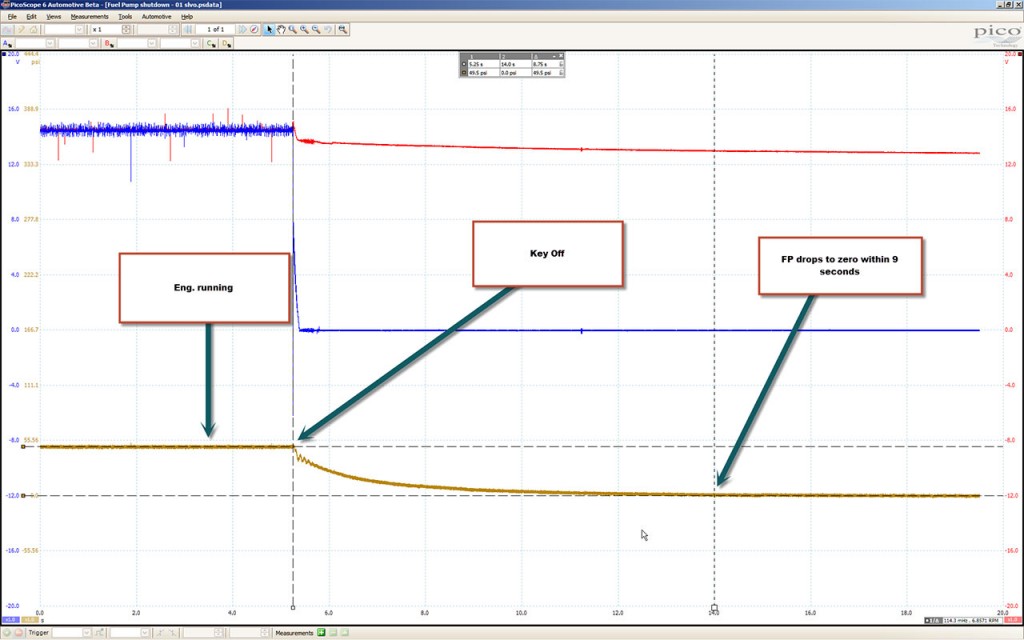

The customer’s concern was hard starting. It would start but had an extended crank time. It would eventually start after the 3rd or 4th attempt. The symptom was more pronounced after sitting for extended periods of a few hours or more. Here are some diagnostic Oscilloscope captures taken during the fuel system testing procedure. You can see how the fuel pressure is somewhat low with the engine running.

The fuel pressure regulator functions okay and the pump’s RPM’s are within normal operating range for a 10 segment pump. The current (amperage) load is not within specs. Notice how the fuel pressure drops off to zero within 10 seconds after the engine is shut down.

This is an abnormal pressure drop. This is the cause of the customer’s concern. A normal pressure drop should be less than 5 PSI after 15 minutes. The running fuel pressure should also be closer to 55 PSI. Cutting the old pump open for a visual inspection reveals the commutator bars looked okay. The pump’s internal fuel return check valve had failed allowing this abnormal pressure drop after pump shutdown. The initial pump prime of 2 seconds at key on couldn’t produce a high enough pressure to start the engine. After a 3rd or 4th key cycle the pump prime pressure increase was enough to start the engine. Always verify the cause of failure before replacing parts. Also verify proper operation after all parts replacements. The fuel filter was also replaced with the fuel pump to protect it from possible filter restriction damage.

To ZOOM for a larger image, just click on them.

This capture shows fuel pressure from key on engine off, to start up and engine running along with a fuel pump input voltage monitored channel at the pump and the relay output channel at the fuse block. This also checks for possible voltage drops in the fuel pump feed circuit. Voltage drops can cause low pump output problems that could lead to incorrectly diagnosed fuel pump replacement.

This capture shows the fuel pressure drop at shutdown. There is no substitute for a dynamic system test. This information is invaluable for proper fault verification to facilitate proper vehicle repair. No guesswork as to what’s wrong here.

1999 Audi A6 3.0L V-6

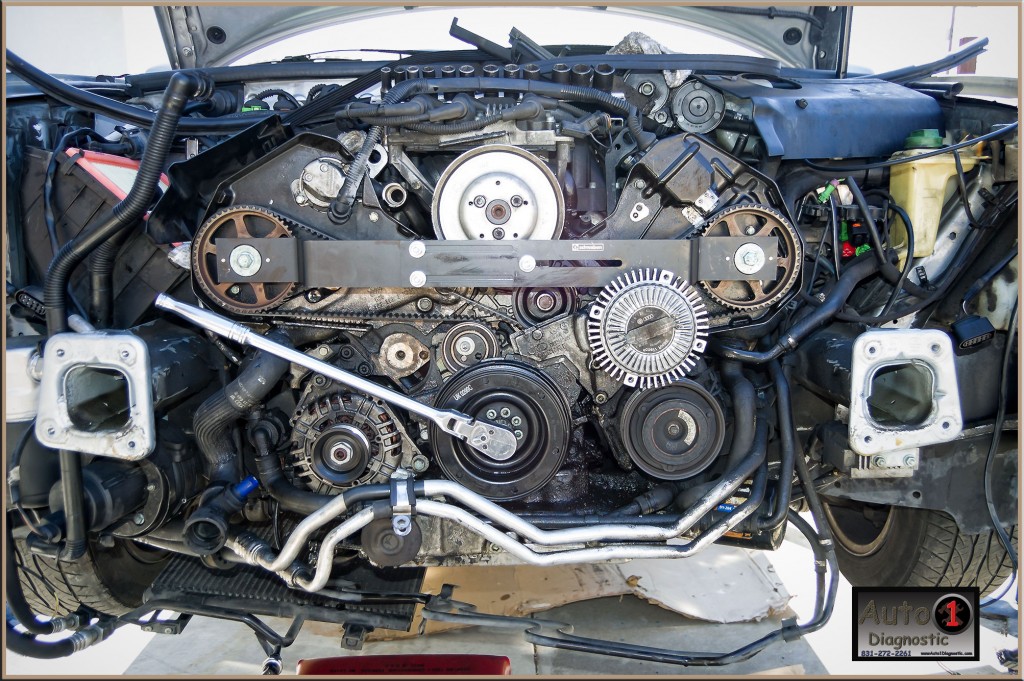

The customer said it was over-filled with oil and leaks when running. I used my Smoke Wizard smoke machine to diagnose the leak and found it at the front crankshaft seal area. I advised the customer to replace the seal and the timing belt. After removing the front end and the balancer, I found the oil seal pushed out of the front cover. The excessively high oil pressure forced it out. I replaced the belt and the seal. What an oily mess!

2003 Cadillac DHS 4.6L V-8

This is a 2003 Cadillac DeVille-DHS. The customer said that the tach and speedo had stopped working while driving. After some diagnostics and research, I found that the ignition 1 fuse had blown. Time to find the shorting circuit. It was necessary to isolate 7 circuit feeds from the ignition 1 fuse. The fault was intermittent and it took some time to isolate the 7 feeds down to the shorting circuit. Circuit isolation is the only way to pinpoint this type of fault when a single fuse feeds power to multiple components within the system. After narrowing it down to the rear integration module (RIM) and the rear object sensor control module (ROSCM) circuits, I was able to find that the harness rubbed through in the right rear sail panel pinch weld area and was shorting the power feed wire to the rear object sensor control module. The scan tool had communication with the module until the fuse would blow. 4 modules would stop communicating. The MIL lamp would also shut off. This looked like a PCM fault at first glance and very well could have lead to false PCM replacement, if not for diagnostic due diligence.

This one was a true automotive bug hunt.

2006 Audi A4 2.0L Turbo I4

Today’s fun job is an Audi A4 driver’s window problem. The customer’s concern is that the driver’s power window binds and stops working. Removal of the driver’s door panel revealed a faulty window regulator. This one is a big job and requires complete door frame and window removal to get the regulator out. Due to the extent of labor costs and the complexity of this job, I advised the customer to only use a factory replacement power window regulator. This assures a quality repair with a nationwide, Audi factory 12-month/12K-mile warranty.

This is the added benefit of buying a factory (OEM) replacement part.

Welcome to Auto1Diagnostic

Regular Business hours are Monday to Saturday from 8AM to 6PM

Call Auto1Diagnostic@ 831-272-2261 for more information. Thank You!